|

Lafayette KT-135 EXPLOR-AIR radio

kit |

|

|

|

|

|

|

|

Since the radio is working, let's

perform an experiment! |

|

|

|

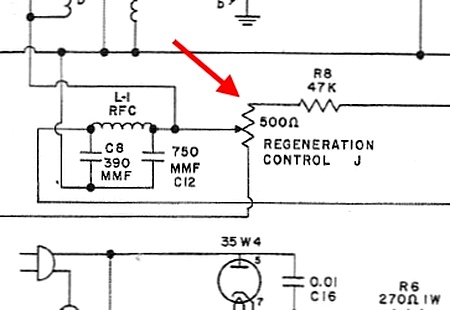

The schematic in the manual shows the

regen control wired this way. |

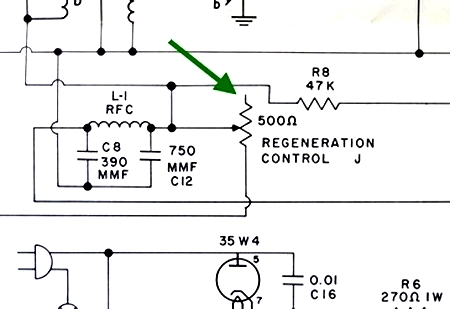

The pictorial instruction sheet says to wire it like this. |

|

|

|

|

|

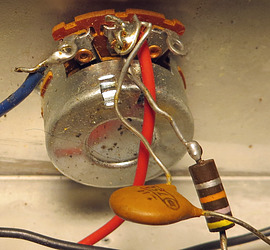

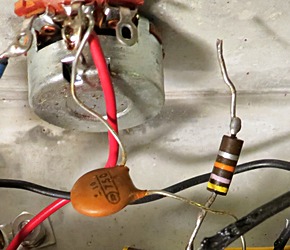

| Which way works better? We

need to cut the lead to the resistor at the regen control,

then compare how the radio operates with it connected to the

right hand lug vs. the center lug. When I touched the

resistor it

broke at the arrow! That actually made things easier.

|

|

|

|

|

|

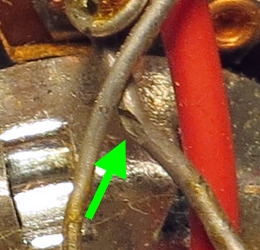

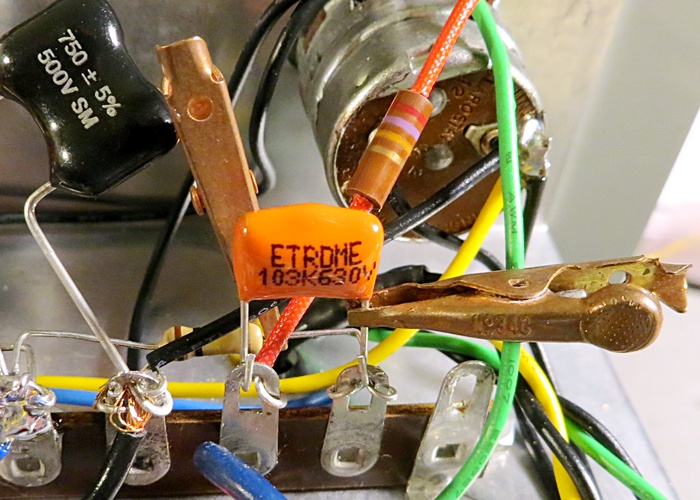

Now we have the black alligator clip

on the resistor, the green clip on the center terminal of

the regen control and the white clip on the right hand

terminal. I had fantasies of flipping the

switch and observing a fantastic increase in performance. In

reality, all that happened was that the regeneration control

needed a tiny adjustment as you switched back and forth.

NOTE: The schematic in

the manual is incorrect. There is no connection on one side

of the regen control.

|

|

|

|

|

|

|

Experiment over. Let's take this thing

apart! |

|

|

| Right from the start there were

problems. I couldn't get the frickin' knobs off! Two of them

had broken set screws. One of them (the one pictured still

attached) didn't

seem to have a set screw with a head on it, so I started to

drill it out. Andrea came to take a look. There was NO set

screw. The knob was GLUED on. What a mean trick! I had been

drilling into the shaft of the volume control. That dirty

bum! (As Ralph Kramden would say.) |

|

|

|

|

|

|

|

|

|

|

|

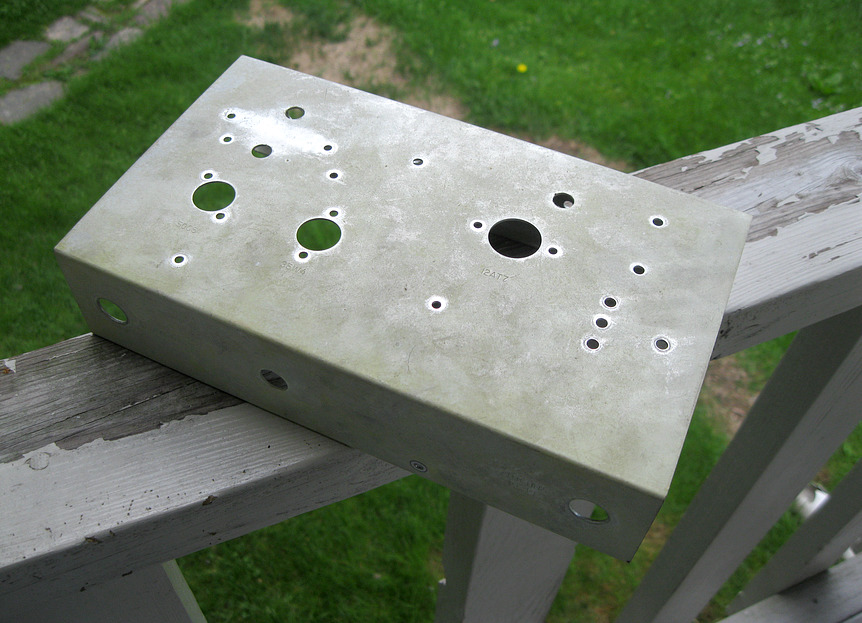

The greenish coating on the chassis

is oxidized cadmium. I was advised not to sand it or breathe

the dust, so I used Duro "TUB N' SINK JELLY" which is

normally used to remove calcium and rust. I then polished it

five times with Brasso. I wanted it to remain dull, but it

kept getting shinier and shinier. The more I polished it,

the shinier it got. There must be a connection, but it

escapes me entirely.

|

|

|

|

|

|

|

|

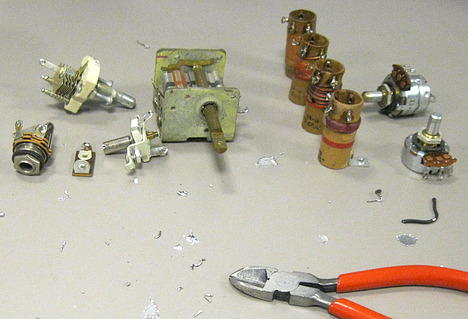

| The collected parts. The fixed

capacitors will be replaced with silver-mica types for

improved stability, except for the .01 bypass caps which are

"Orange Drops." The "Chatter Teeth" (top left) are

not part of the project. |

|

|

|

|

|

|

This is what you got when you opened the box 50

years ago. I stole this picture from

|

virhistory.com. |

|

|

|

|

|

Using the photo on the left I've identified

the tubes in this particular kit as "IEC" by the boxes. The tube boxes were

magically restored in the picture on the right.

|

|

|

|

|

|

|

|

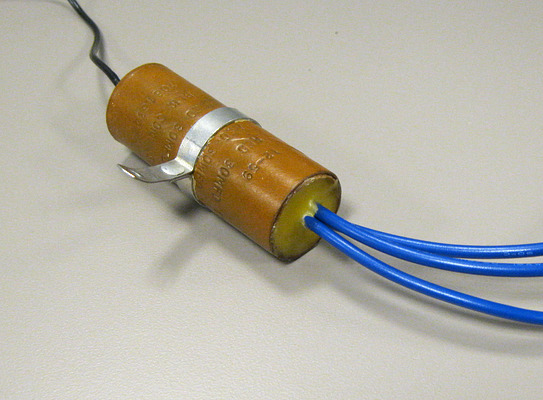

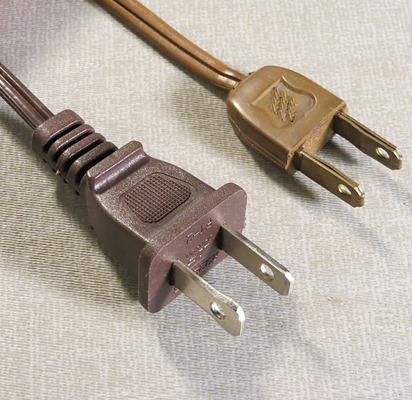

| The original capacitor was restuffed

and sealed with beeswax at each end (I didn't have any red

wire). The set was also going to get a

polarized plug since there was a 50/50 chance the chassis

would be "hot" every time you plugged it in. |

|

|

|

|

|

|

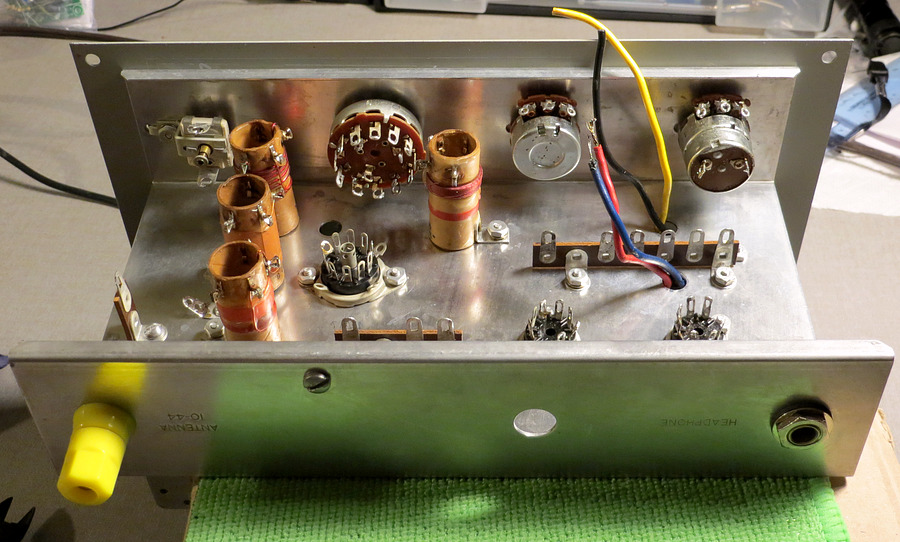

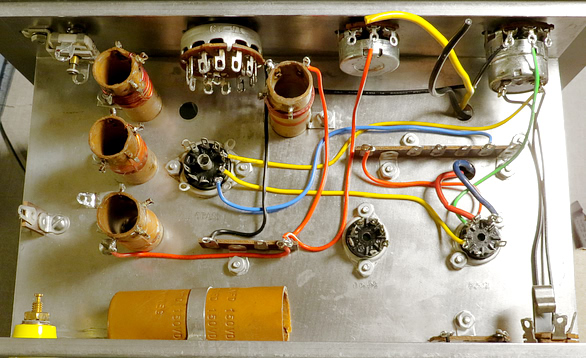

|

Main parts are mounted. Notice the red

antenna connector. |

|

|

|

|

| The

antenna connector, which was black, was replaced with a red

one. Someone pointed out that neither color should be used

for an antenna and convinced me to get a yellow one. This

style is getting hard to find. |

|

|

|

|

|

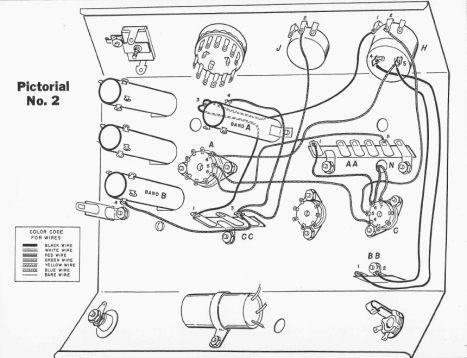

| How it looks in the manual vs. how

it looks in real life. Pictorial No. 2 makes you think it

will be easy to wire the set. Then you get to Pictorial No.

5 and things aren't so easy anymore. (A copy of the manual is on the

bottom of page five.) |

|

|

|

|

|

|

Small

alligator clips were used as heat sinks to prevent damage from the soldering iron. |

|

|

|

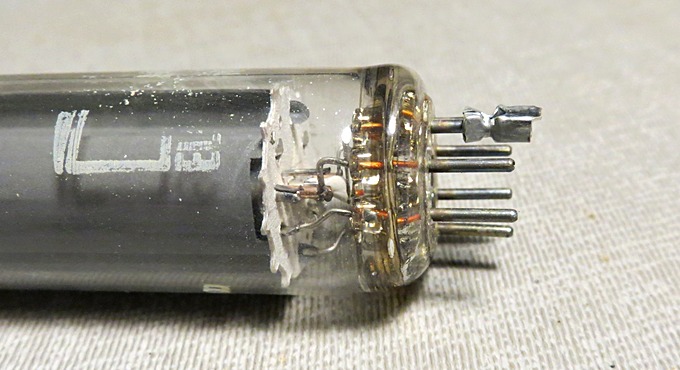

The vacuum tubes. |

|

|

|

|

Inside your KT-135 you'll likely find an IEC

35W4, an IEC 50C5, both made in Japan, and an IEC 12AT7 made

in Great Britain. IEC, or International Electronic

Components, rebranded vacuum tubes at a factory in Long

Island, NY. You may also find Sylvania or Lafayette brand

tubes.

In 1965 Lafayette sold GE, RCA, Mullard and

Sylvania brand tubes. In 1966 the Sylvania brand was

replaced with Lafayette, so that can help narrow down the

date of the radio. The Lafayette 35W4 and 50C5 were

rebranded Sylvania

tubes, but the 12AT7 was made by Mullard,

contrary to their "Made In USA" claim in the

catalog.

Sometimes it's obvious the original

tubes have been replaced, especially if the radio was sold

online. The tubes were scavenged from the KT-135s in the

1960s and '70s to be used in the family table radio, then

replaced by a seller 50 years later. For example, Lafayette

didn't supply tubes labeled Sears Silvertone or

Motorola with the KT-135 kit, so these were pulled from

another radio, as were tubes labeled Admiral, Emerson, or

Philco. The original 12AT7 will sometimes be in place

because they weren't used in superheterodyne radios.

In the 1966

Lafayette catalog, a Lafayette 35W4 was $0.48 and a 50C5 went

for $0.90. A 12AT7 was $1.29. They didn't sell the IEC brand

tubes, even though you got three with the KT-135.

IEC went bankrupt in 1980,

long after the KT-135 kit was out of production.

|

|

|

|

|

|

|

| When this radio was being restored I

was unable to acquire IEC brand tubes. Three "New Old Stock"

vacuum tubes were purchased, and one of them was a Lafayette

just by chance. I got them at

vivatubes.com. |

| |

|

|

|

|

|

|

|

|

Above is one of the tubes after it was removed from its

socket. Part of the socket is still attached to the tube.

Obviously the radio isn't going to work again when the tube

is put back. The Lafayette tubes had a 2-year guarantee

(the IEC had none) but they supplied low quality

phenolic plastic tube bases with the KT-135, which sold in the

catalog

for 18 cents.

It's doubtful anybody ever did this, but you could go into

the Lafayette store and upgrade to a Bakelite socket for 31

cents. Whaaaat??! 31 cents?! That's almost double the price, those

thieves!!! |

|

|

|

|

|

|

|

|

|

|

|