|

Lafayette KT-135 EXPLOR-AIR radio

kit |

|

|

|

|

|

|

|

Making a Cabinet |

|

|

|

|

The Lafayette Explor-Air

radios appear on ebay several times a year.

Sometimes they don't have a cabinet. The cabinet was

sold separately and not everyone bought one or could

afford one. The cabinet cost $3.49 in 1968. In 2025

that is the equivalent of $32.50.

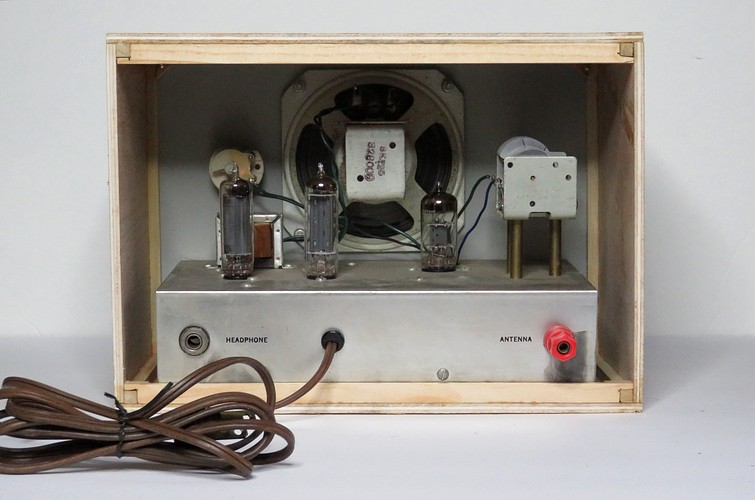

It's neat to listen to the radio and peer over the

top of the front panel and see the tubes glowing,

but the chassis is open at the bottom and is a shock

hazard. Components and coils underneath can be damaged.

On top, the variable capacitors can be bent and

shorted, vacuum tubes might be broken. The

radio should have a cabinet. |

|

|

|

Let's build a cabinet for a KT-135! |

|

Note: These are not

"instructions." This page just

shows how I made a cabinet. |

|

|

|

|

|

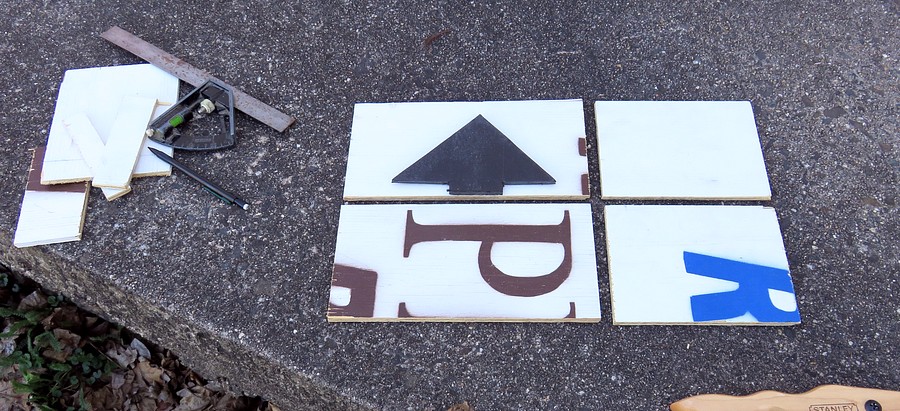

The cabinet is made of

3/8 inch plywood. I happen to have some 3/8

inch plywood, in the form of a half dozen signs we

made for the Pritz family reunion back in 2005. (I

was married to the granddaughter of a man named

Peter Pritz. In the 1930s Peter Pritz invented the soda machine - the kind where the cup drops down and

fills up with soda syrup and seltzer.)

There's just one problem. This plywood was

the cheapest crap you could buy. The signs were left

outside at various intersections overnight, then

stored in the garage for 13 years. They are very

warped.

The only tools I have are a hand saw and a palm

sander. Not only that, my wood working skills are

abysmal. Nevertheless, I'm going to try to make a

cabinet. |

|

|

|

|

|

|

|

|

I used non-warped sections

of the signs and cut out the top, bottom and sides.

Most people could do this in ten

minutes but it took me an hour. 'Tis a poor

craftsman who blames his tools. Damn tools!

|

|

|

|

|

|

|

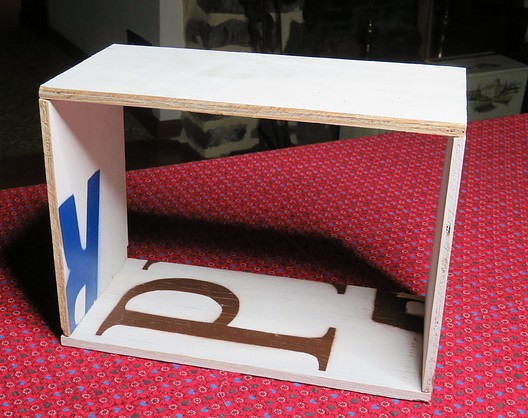

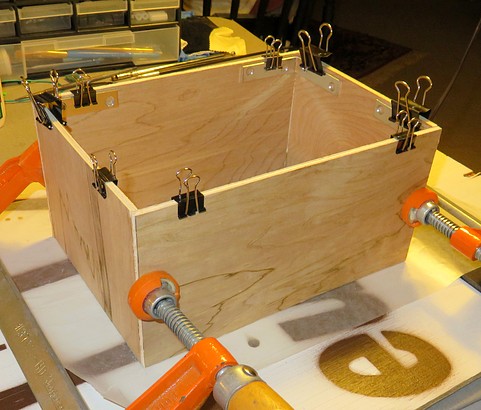

The panels were glued and

clamped. The real cabinet from Lafayette Radio has dovetailed joints but

I have no way to make anything

so sophisticated.

The

glue used was Titebond III Ultimate Wood Glue.

Rated #1 by Pros, so it says on the bottle. The Titebond people

know how to make glue. I was amazed at how strong the

box was the next morning. |

|

|

|

|

|

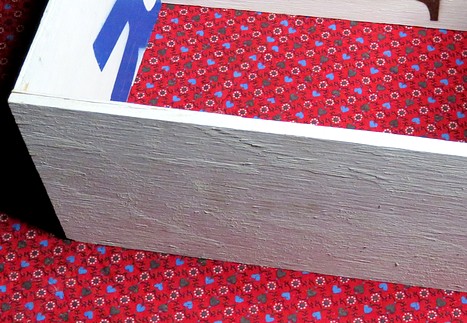

This came out better than I

thought it would! However, it was time to

reconsider making the cabinet with this plywood. How much effort

was it going to take to go from a plywood box to a

radio cabinet? The wood I was using was not

appropriate, no matter how much I intended to sand

it. It was time to get a decent piece of 3/8" plywood.

NOTE: I stored this in a garage, where it

froze during the winter and baked in the summer. Two

years later I

dropped it and it fell apart! One problem was that

the surfaces were painted before they were glued, so

the glue never went into the wood. A few tiny nails would certainly have helped

hold it together. Use brads or nails in addition to

the glue when making your cabinet. |

|

|

|

|

| It was off to Lowe's for a

nice piece of plywood. Unfortunately the 3/8"

plywood stocked on the shelves was in worse

condition than the 13 year old Pritz Reunion signs.

It was total junk I wouldn't have taken for free. I

bought "Luan" plywood. It's 5.2 millimeters thick, a

bit less than 3/8" but it was a LOT easier to saw

through. |

|

|

|

|

|

|

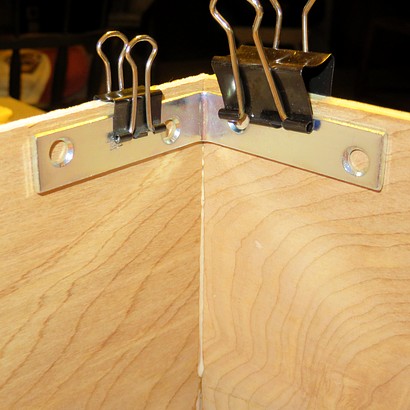

Andrea came up with an idea to use

corner brackets to keep the box square. |

|

|

|

|

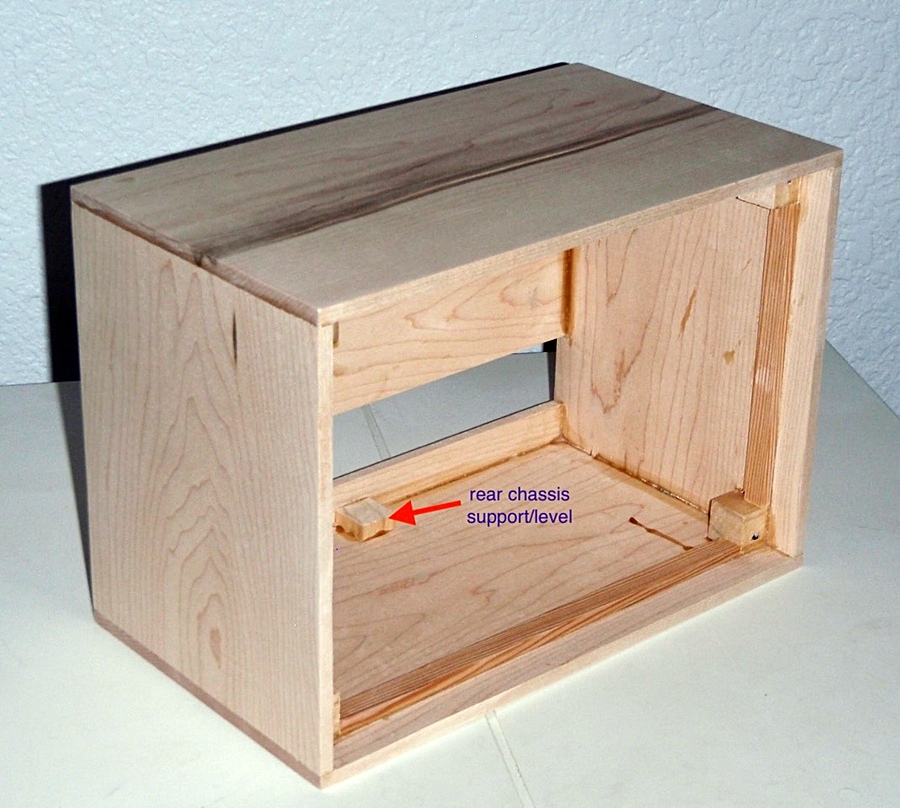

All four corners are now reinforced with

1/4" poplar trim. When the box was

assembled, all the factory cut sides faced front.

All my wonky hand cut sides face rear. They'll be

sanded with an electric palm sander before the back

is attached.

|

|

|

|

From the back, after thicker 5/8"

trim was added top and bottom. It is now very strong but

lightweight.

If using actual 3/8" plywood, the trim pieces in the back

aren't necessary. 5.5 inches of clearance are needed for the

chassis.

|

|

|

|

|

|

|

|

|

|

| Now it was time to test fit

a radio inside the cabinet. If it didn't fit there

was no sense in wasting time making a back for it.

The radio fit well, though the cabinet is about

1/16" out of square on one corner. Nobody will

notice once it's covered. |

|

|

|

|

|

|

|

|

|

The cutouts in the back panel were made

with a coping saw. |

|

|

|

|

|

The coping saw makes a wavy cut that

needs to be filed straight. |

|

|

|

|

|

|

|

| The finished

cabinet. All corners and edges have been sanded

round. |

|

|

|

|

|

|

|

|

Now it was time to cover the

wooden cabinet, but with what? A close look at an

actual cabinet shows it appears to be covered with

vinyl wallpaper! How to score some vinyl wallpaper?

I had a plan. Yes, a CLEVER plan. I'd buy a

wallpaper sample.

I went online and found a really nice vinyl

pre-pasted wallpaper. It was $1.10 a foot but you

have to buy two 16.5 foot rolls. However, you could

order a sample for $5.99.

If the wallpaper is $1.10 a foot and a sample is

$5.99, how much do you think you'd get? At least

three feet, right? |

|

|

|

|

|

|

They sent a foot!! |

| When I complained that I was

hoodwinked into buying $1.10 worth of wallpaper for

$6, a nice person named Lori told me that it was the

industry standard for a sample. She agreed it was

too small to tell what an entire room would look

like and sent me another sample. |

|

|

|

|

|

|

|

While waiting for the other wallpaper

sample to arrive, "Plan B" showed up in the mailbox. I had

ordered a roll of Tolex from ebay. |

|

|

|

|

|

The cabinet corners were painted black

in case I messed up one of the cuts. |

|

|

|

|

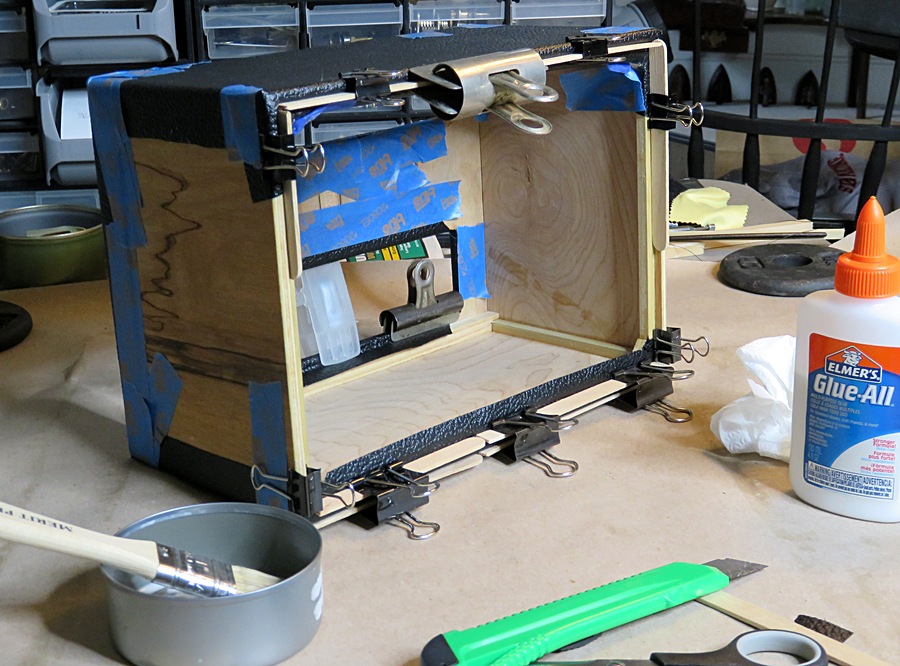

The plan was to use white

glue, which is probably the wrong stuff to use. The

back of the Tolex was covered with glue, then the

cabinet was placed on it and the Tolex was just

pulled over the back and top.

I quickly found that Tolex does NOT go on like

wallpaper. It will not take a crease unless you

force it to. (I suspected this might happen,

considering the thickness of it.) Before the glue

set, I had to find spring clips, popsicle sticks and

masking tape to get it to do what I wanted.

The question now is how is the glue supposed to dry

when it is covered with vinyl? |

|

|

|

|

|

| The next day, the sides went

on much easier. Since I now knew how the Tolex

behaves, all the clips, popsicle sticks and pre-cut

pieces of masking tape were standing by. |

|

|

|

|

|

|

|

|

|

Finished! Not perfect, but not too bad

for a first attempt. I think the glue is still wet under the

Tolex. |

|

|

|

|

|

|

|

|

|

|

|

The materials used cost about $15.00,

the equivalent $2.06 1968. I saved about $10.40 in 1968 dollars

by making it myself.

|

|

|

|

|

|

|

This one sold on ebay in March of 2022. |

|

|

|

|

|

|

|

|

This cabinet was made by Jeffrey

Hutchinson of Oregon in 2023. |

|

|

|

|

|

A nice home for a KT-135. |

|

|

|

Next, the KT-135 goes to the Moon! |

| |

|

|

| |