|

The

OZARK PATROL |

|

|

|

|

CONSTRUCTION |

|

The kit doesn't come with any

instructions. They must be downloaded from the 4 State QRP

website. On the first page it states that construction

should take about two hours. Under "First Steps" it says to

organize the parts first. Don't get the idea that you're

going to actually be done in two hours. From the time you

open the box till the time you've got your parts counted an

hour will have gone by. |

|

|

|

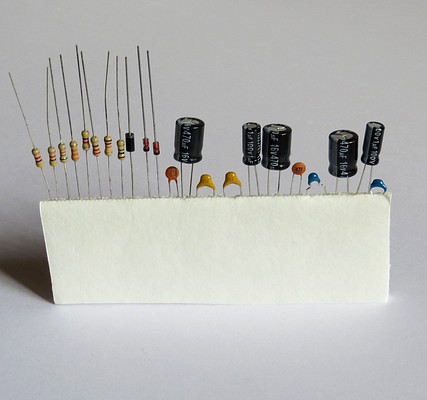

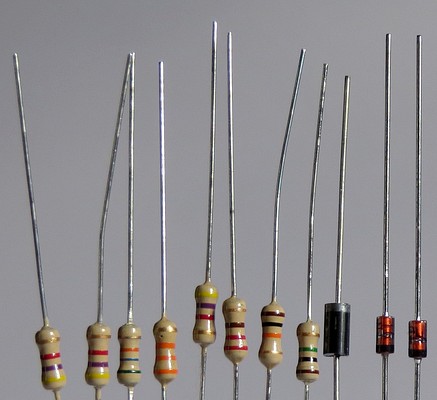

Since you have to count the components, line

them up in the order they will be used, then double-check as

you solder them in.

If you examine the parts closely you might see oxidation on

some of the leads. Instead of being bright silver they may

be gray. This must be removed if you want a good solder

connection. Just pull them through a small piece of "Scotch

-Brite" or fine sand paper before you solder them in. |

|

|

|

|

|

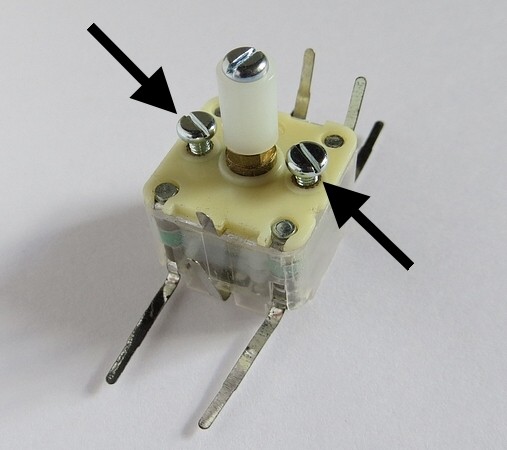

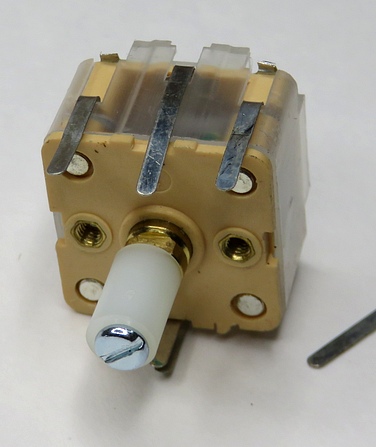

When you pick up the variable

capacitor, the first thing you do is turn the shaft; it's

just human nature. DON'T DO IT. If the screws provided to

mount the capacitor are turned all the way in, back them out

or remove them. OK, now you can turn the shaft. To tighten

the shaft extension, hold the shaft with a pair of

needle-nose pliers. |

|

|

|

|

|

|

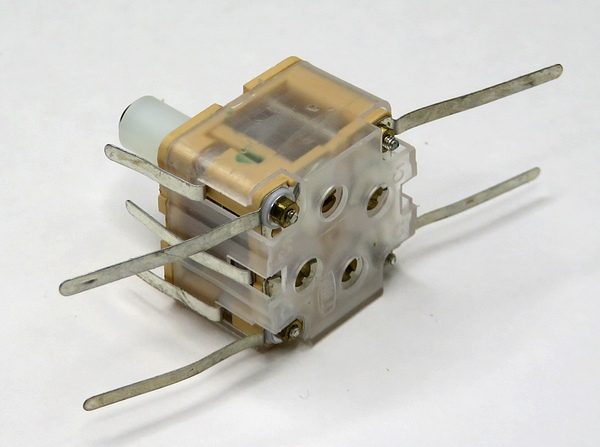

While installing the capacitor, spread out the four tabs on the back corners and cut

them off. Push all the other tabs forward. |

|

|

|

|

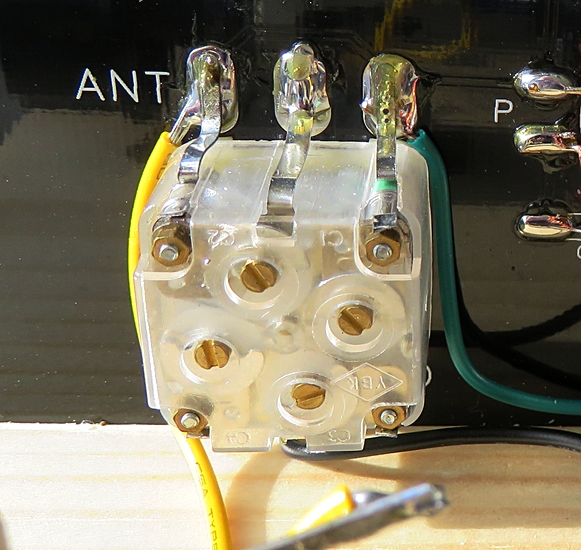

It looks like this when you're done. |

|

|

|

|

|

|

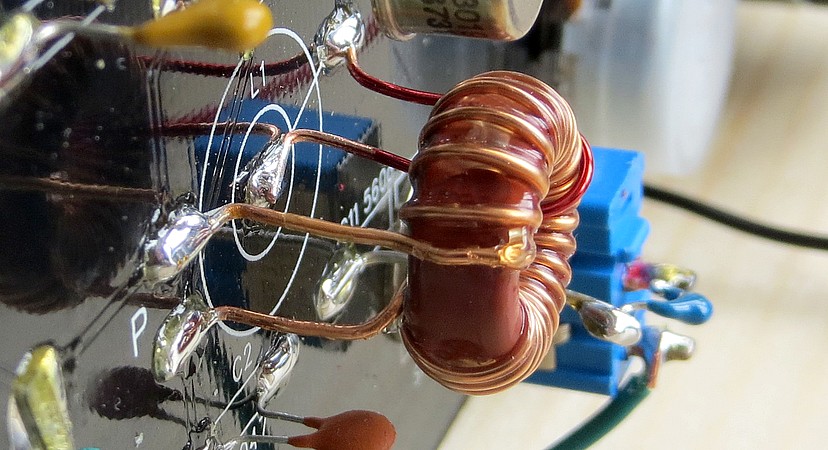

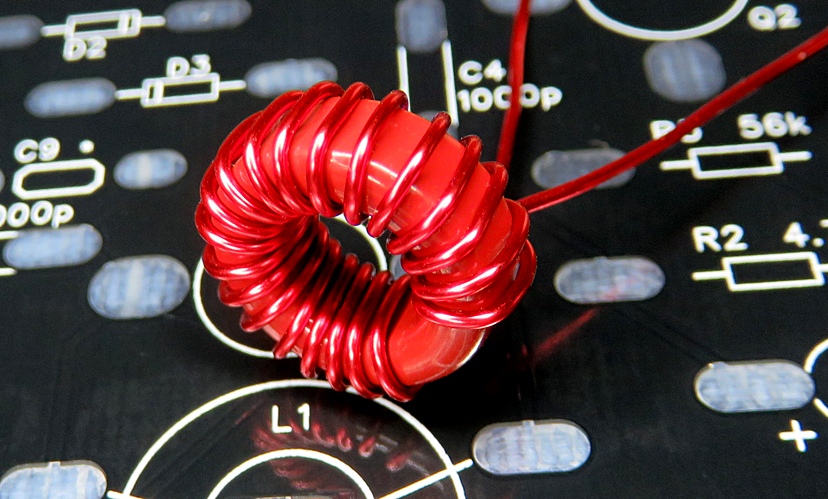

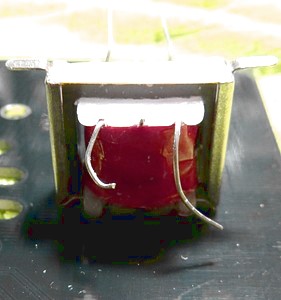

The first part to be soldered

to the board is the coil.

The 22 gauge magnet wire supplied was rather twisted up. It

was impossible to get the kinks out, so I used my own wire.

I also gave the coil two coats of polyurethane, so it ended

up being the last part installed instead of the first.

Someone wrote in and asked my if I used a brush for the

polyurethane. No, I dunked it in the can. |

|

|

|

|

|

|

The instructions say to mount the coil

flat, but I raised mine away from the grounded panel. For

all practical purposes, the magnet field lines in a toroidal

coil are inside the coil and should have no unwanted

coupling with the panel, but ya never know! Everything I've

learned about tuning coils told me to never put the coil

near a grounded metal object |

|

| |

|

|

|

My set had too much feedback.

I put some space between the coil and the tickler

wire to improve the action of the regeneration control. |

|

|

|

|

|

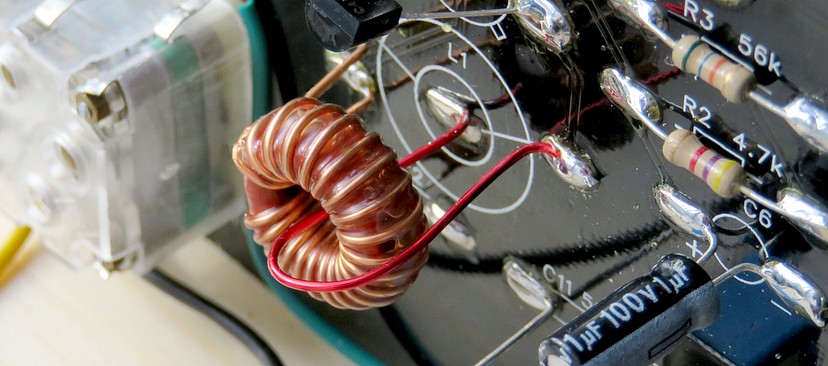

| Here's another coil. Winding the coil

can be difficult because it is so small. The length of the

wire required is about fourteen inches. The hank of

wire that comes with the kit is four feet long. Cut the wire

in half and you will have plenty, but won't have to thread

four feet of wire through the toroid twenty times. |

|

|

|

|

|

|

|

|

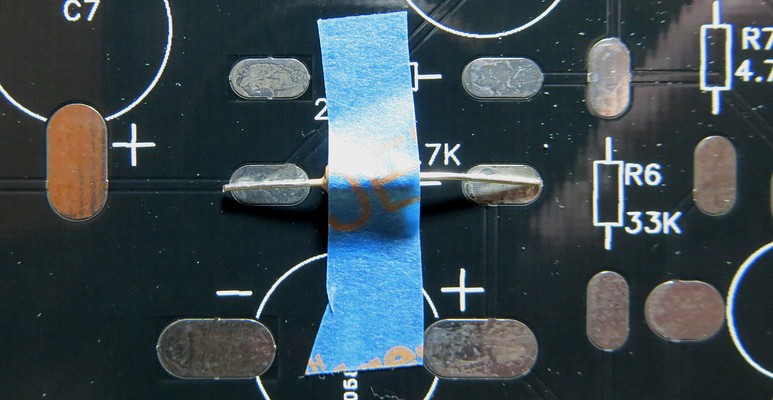

The manual gives

instructions on how to solder the parts in, but I didn't follow

them. From the way I saw it, you need three hands.

My third hand was a strip of painter's tape. I used the same piece

over and over. Here is the first resistor about to be soldered. |

|

|

|

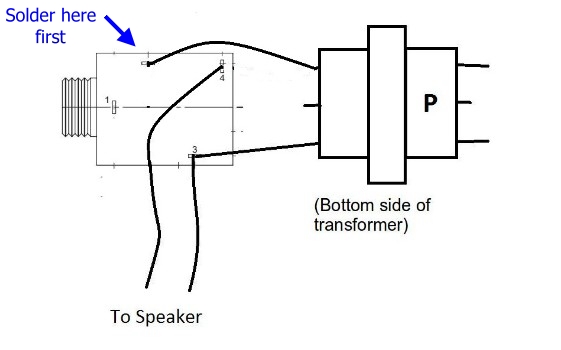

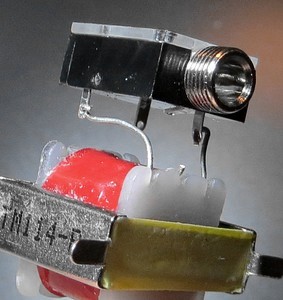

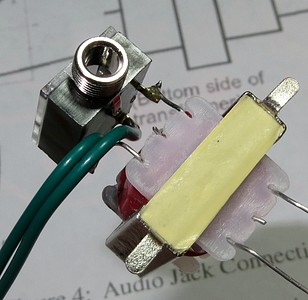

Now we come to

another reason you will not complete the kit in two hours. The

headphone jack is mounted just a little

too close to the transformer for easy assembly. The

wiring diagram on the left shows the bottom of the transformer and

the side of the jack. In reality, the bottom of the transformer

and the front of the jack both point in the same direction.

|

|

|

|

|

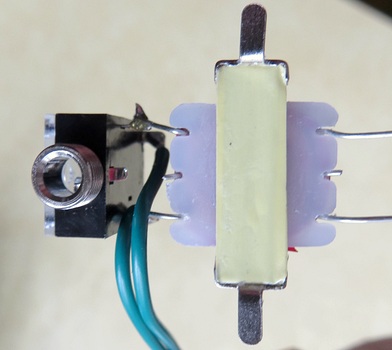

NOTE: The side of the transformer that is

soldered to the front panel has the letter "P" stamped on

it. The jack is connected to the other side.

This is one way to assemble the two

parts:

1. Cut off the center leads from both sides of the

transformer.

2. Wire the leads according to the diagram, but with the

jack pointing down. Bend and cut the leads after making a

test fit.

3. Push the leads into the holes in the jack terminals and

crimp them.

4. Solder the connection shown upper left in the

diagram. This will hold things together.

5. Crimp the speaker wires around the jack terminals and

solder the remaining two connections.

6. Insert the jack into the front panel and attach it with

the lock nut. Squeeze the two components together until the

transformer sits on its solder lugs.

Welp, there goes your two hours. Finished yet? |

|

|

|

|

|

|

The primary side of the transformer is marked

with the letter "P." |

|

|

|

|

|

|

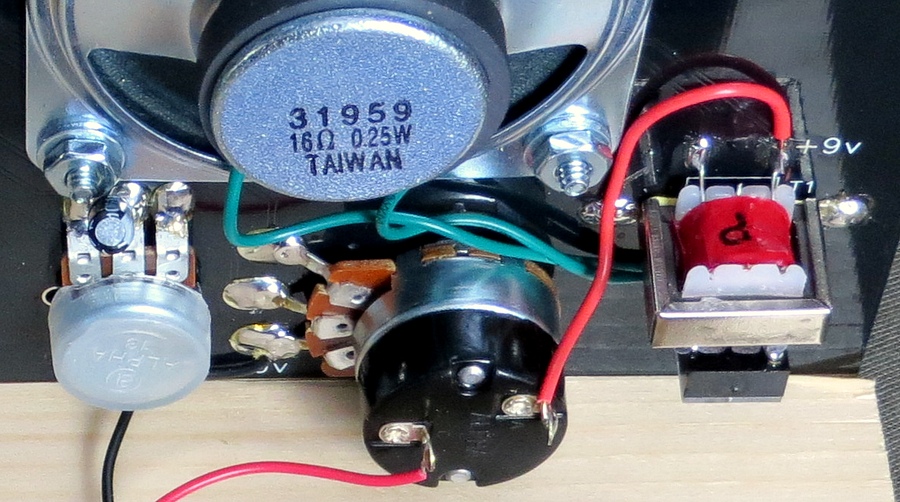

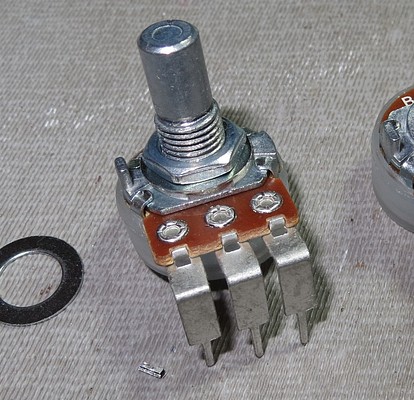

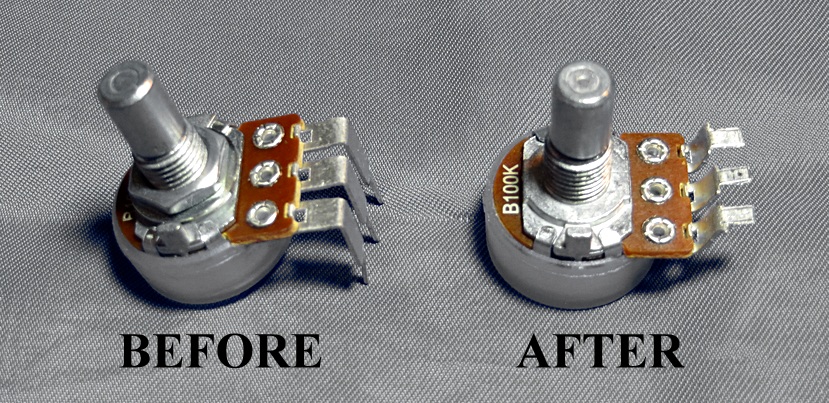

The terminals on the pots face the wrong way! The

instructions say to just bend them. Grab a decent pair of wire

cutters first. |

| |

|

You'll have to bend them AND trim them to make them

fit. Add another hour. |

| |

|

|

It took me over six

hours to build this, so don't feel bad if the "two hours" has come

and gone. Who wants to slap it together in

two hours anyway? Spend an hour on it, put it aside, then come back

to it later. Don't forget to unplug the soldering iron.

|

|

|

|

|

|

|

If you get the "correct" parts, just bend the

terminals down like it says in the instructions. |

|

|

|

|

|

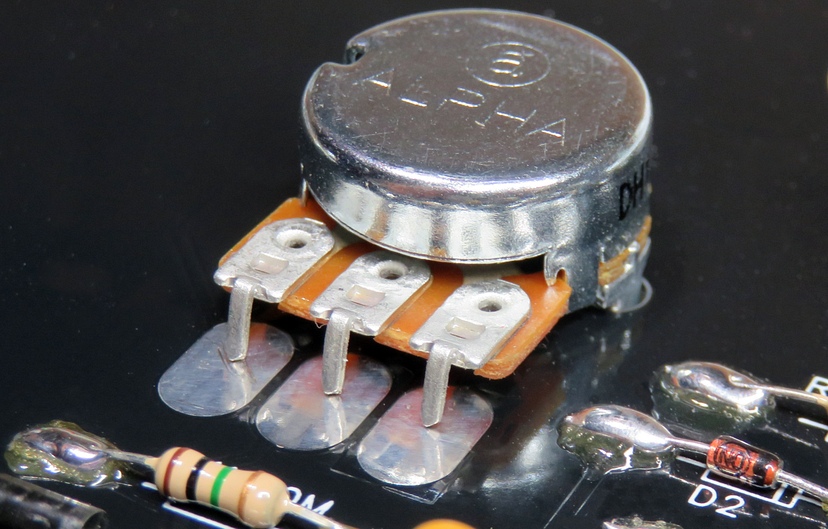

Make sure the terminals are touching the solder

pads. |

|

|

|

|

|

|

|

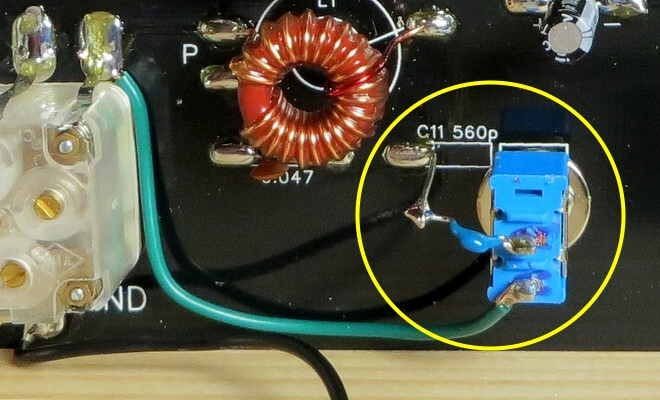

The band switch was

wired per the instructions, but it works backward. The low band is

up and the higher band is

down. No, I didn't put it in upside-down, but I should have. It

drives me crazy. It's a simple toggle switch that puts

capacitor C11 (560p) in parallel with C1 (main tuning). When

you install your switch make sure the ON position is DOWN.

The regen control has a reverse action.

You turn it full clockwise, then turn it counter-clockwise to add feedback.

The instructions say to do the opposite. The instructions

also say to turn the volume control fully clockwise when you

turn on the radio, so the radio is at maximum volume and at

maximum regeneration as soon as you turn it on. I hope

you're not wearing headphones. It's probably a mistake in

the manual, or even a practical joke. |

|

|

|

|

| |