Modern Radio Laboratories

® /Alfred P. Morgan Mash-up

|

|

Making the coils.

Determining which wires go to which pins. |

|

|

|

Elmer Osterhoudt and Alfred P. Morgan both give

instructions on how to wind the coils and both are hard to

comprehend. Morgan advises to just buy the coils, but

gives instructions on how to wind a coil on a Bakelite coil form.

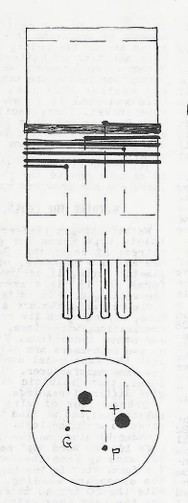

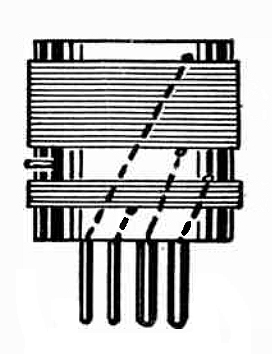

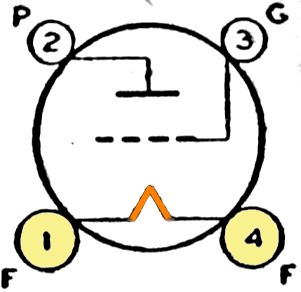

Elmer wants you to follow the diagram on the left, drawn in his

typical style with no perspective. Are you going to buy blank coil forms and wire, and try to

wind a coil based on this perplexing drawing? Better just buy the coils already made from MRL. This lousy drawing

is good marketing.

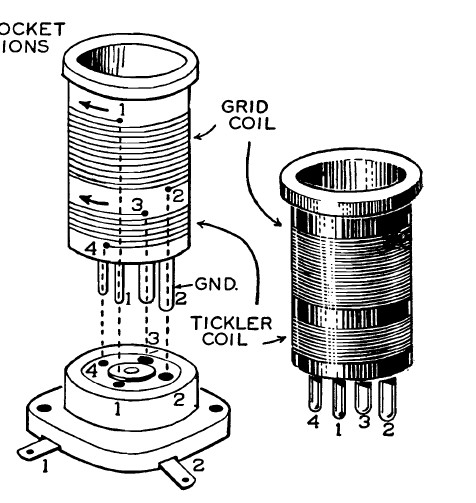

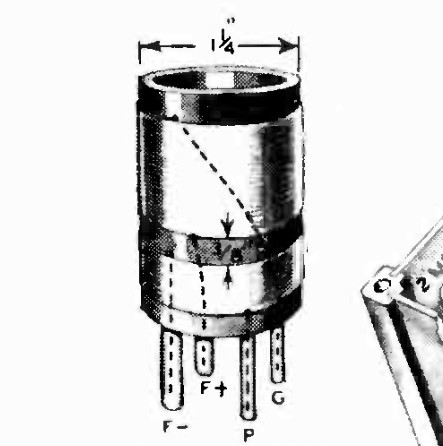

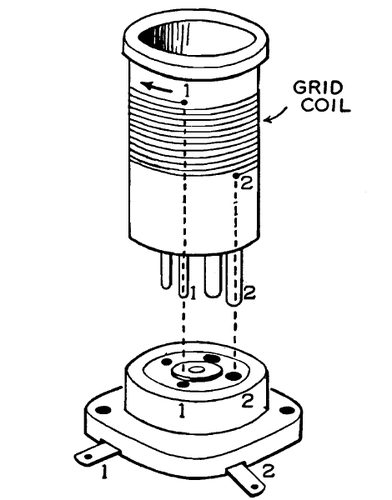

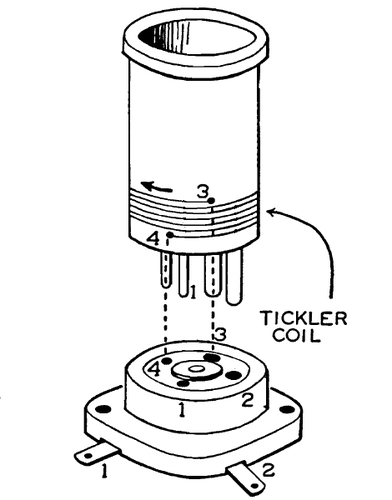

The superior drawing in Morgan's book is still

confusing. Above, on the far right, pins 1 and 2 on the coil are closest to

you, and pins 2 and 3 are the fat pins. Once you see

that one fat pin is in the rear, the drawing becomes clearer.

|

| |

|

|

|

| |

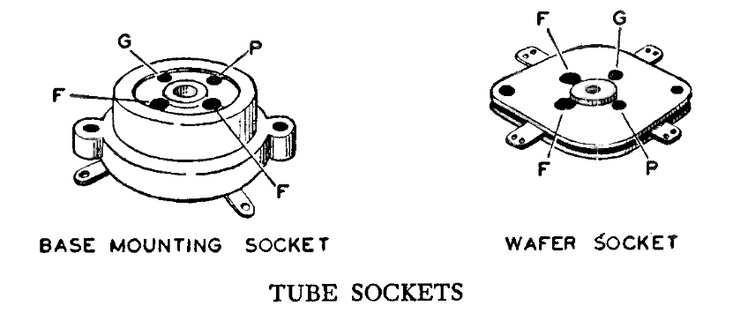

The

circle in Elmer's drawing is the socket. If you mentally tilt

the circle and compare it with the Morgan socket, "P" is pin 1.

Elmer used the designations for Grid,

Plate, Positive Filament (+) and Negative Filament (-).

The reasoning behind this is shown further down this

page. |

|

|

|

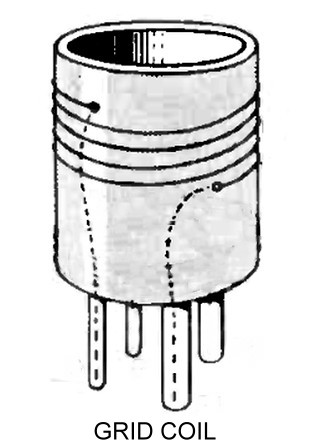

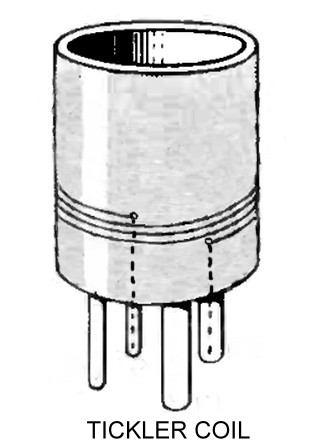

NOTE: The larger of the two coils is referred to as the Grid or

Secondary coil |

|

|

|

|

|

|

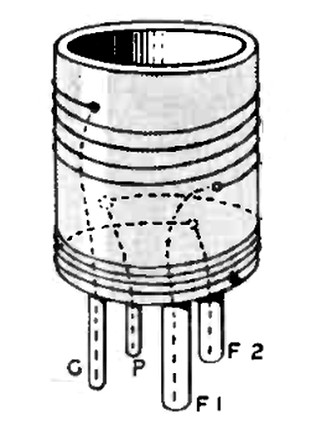

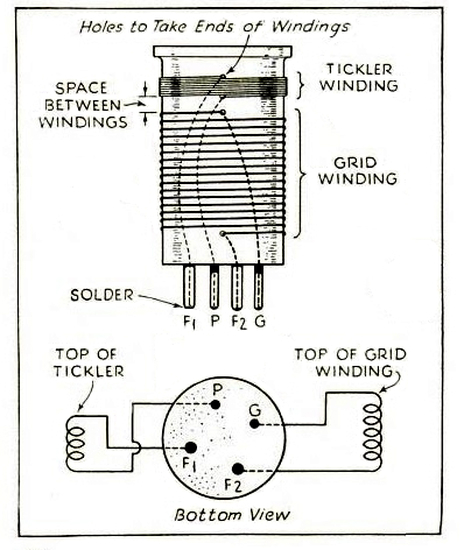

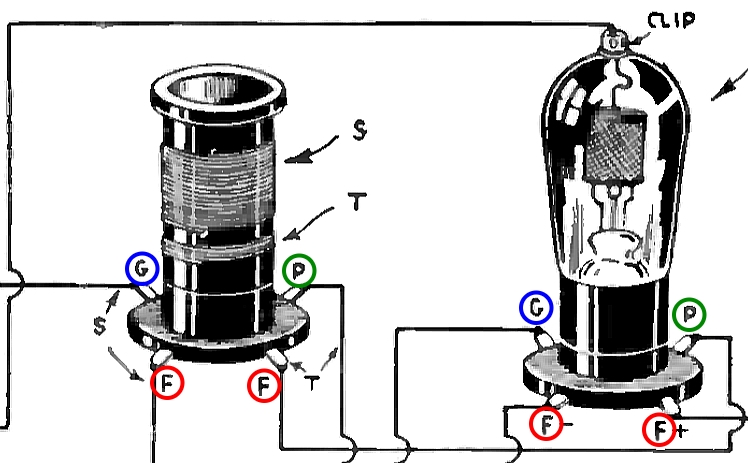

These drawings, from two

articles in Radio Builders Manual

published in 1934, show the same pin connections as in

Morgan's drawing. (Ignore the letters and follow the coil connections to

the pins.) Note that the coils are rotated a quarter turn when compared

with the Morgan drawing.

Once again we

see pins labeled for a filament, F- and F+, or

F1 and F2. Why? After 100 years these

designations, which were once common knowledge

to a radio fan, have me flummoxed and

bewildered. |

|

|

|

| |

|

|

| This is so confusing to me

that I edited the drawing. Each coil is

connected to a fat pin and a thin pin and both

are wound in the same direction. It doesn't

matter which direction as long as they are both

the same. The tickler can be on the top or the

bottom. You can't just pick any pins you want, or

you may end up with a coil that doesn't work. |

|

|

| |

|

|

| The Morgan coil

drawing simplified. |

|

| |

|

|

| From "The Radio

Amateurs Handbook" 1929. |

|

| |

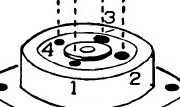

To complete the confusion, the numbers on a four

pin socket don't match up with the numbers in

Morgan's drawings. If I had never seen a real coil, I'm not sure I could

make one based on these drawings.

This explains the guys who say, "I built one of these when I was 10

years old. I've spent my career in electronics thanks to Alfred P.

Morgan." These kids were winding radio coils from

incomprehensible instructions. It is no wonder they were successful

in life. (Actually, one guy who built the Morgan set told me he

became a Geologist, so the "career in electronics" theory is not

rock solid. Get it? "rock" solid. Never mind.) |

The coils are "standard" in the pin configuration. (The only reason

I state this is that Morgan said to buy the coils, and if there

wasn't some standard at the time, the radio wouldn't work.) A 1935

Bud Radio Products catalog states that their coils can be

used in any circuit specifying a four prong coil, so this

configuration dates back at least to 1935, and Elmer Osterhoudt had

been making them since 1932.

|

|

|

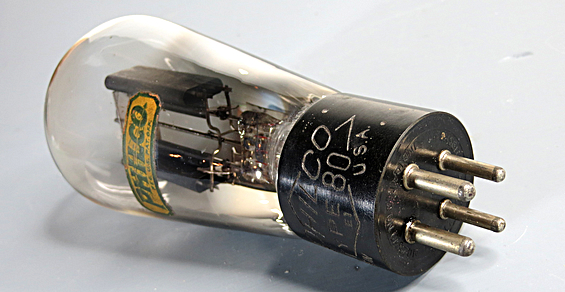

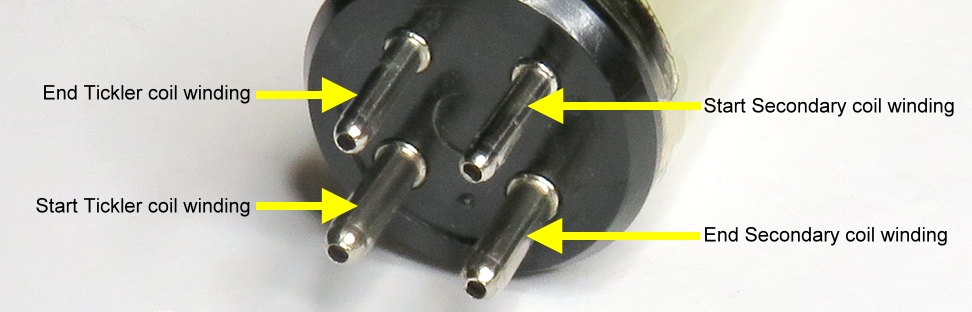

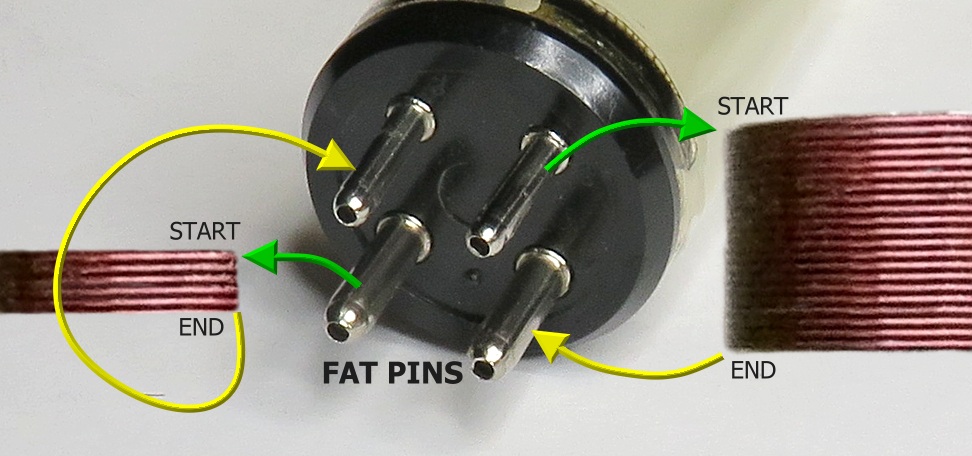

There are two

fat pins and two thin pins. Logically, you'd think that the big

coil would connect to the fat pins and the small coil would connect

to the thin pins, but that's not the standard. Each coil is

connected to a fat pin and a thin pin.

So why is that? A four pin vacuum tube has the filament on the fat

pins. If a coil was wound across the fat pins and you

accidentally plugged it into a tube socket, it would heat up

while putting a dead short across the source of the filament

voltage. There would be a contest inside the radio to see

which would turn into a puff of smoke first; the

transformer, the coil, or the wires going to the tube

socket. |

|

|

|

|

|

|

|

| The pin connections of the two

coils (compare to the drawings). Wind

both coils in the same direction. For example, if you wind the

secondary coil down from the top, starting on pin 1 and ending on pin

2, then also wind the

tickler down from the top, starting on pin 3 and end on pin 4. Both

coils must be wound in the same

direction or the radio won't oscillate. Leave 1/8" between the two windings. |

|

|

|

|

|

|

Here's another way to visualize it. |

|

|

|

|

|

This diagram from 1935 shows the pin labels. |

|

|

|

Another Mystery Solved

Why are the pins designated with letters?

|

|

|

|

|

|

|

|

The logic behind the pin designations on a coil is that the coil used a

tube socket. When you look at a

schematic or pictorial of an old radio, the designations on

the coil don't seem to make much sense unless

you see the coil together with a vacuum tube, as

shown above. The coil socket has the same

labels.

NOTE:

P and F+ connect to the smaller "Tickler" coil. G and F- connect to the main tuning coil, or "Secondary." |

|

|

|

|

|

|

|

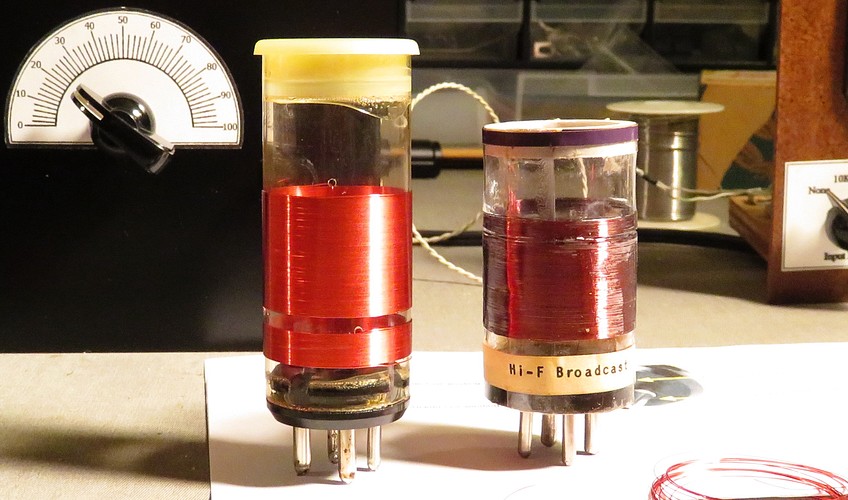

A set of MRL coils.

|

Elmer put the tickler winding on the top, Alfred Morgan put his on the bottom. It

doesn't really matter as long as you wind the tickler and secondary coils

in the same direction.

Though the coils are color coded, I can't find any evidence that

there was an industry standard for the colors. |

|

|

|

|

|

|

"OCTO" brand four pin coils. Red, blue, brown and green.

The red coil might tune similarly to the

red MRL coil, but the other colors don't match. The tickler

winding are on top, like the MRL coils.

|

Since Octo Coils had been around since about

1927, we can consider them to have a "standard" pinout, even if

it's a defacto one. MRL coils pins agree with the Octo Coils.

The side of the box states that this set costs $5. If they

were made in 1930, that's the equivalent of $97 in 2025. MRL coils

were $1.50 for a set of four, or $29 today. They aren't the same

quality, but work better due to the celluloid coil form. |

|

|

|

|

|

Here is

MRL / Morgan comparison data for the AM Broadcast Band coils. Two coils are needed to cover

the band. |

| |

|

| |

Variable

Cap |

Secondary

Coil turns |

Wire

Gauge |

Tickler

Coil turns |

Wire

Gauge |

| COIL 1 |

|

|

|

|

|

| MRL |

10 -

140 |

84 |

28 |

14 |

28 |

| Morgan |

10 -

365 |

70 |

30 |

20 |

30 |

| |

|

|

|

|

|

| COIL 2 |

|

|

|

|

|

| MRL |

10 -

140 |

170 |

34 |

25 |

34 |

| Morgan |

10 -

365 |

150 |

34 |

45 |

34 |

|

Notice Morgan uses less turns on the secondary and

more on the secondary, but he used a variable capacitor that is

double the value Osterhoudt used. Osterhoudt tells us the first MRL

coil will tune from 950 kHz to 2100 kHz and the second coil tunes

from 436 kHz to 1000 kHz. The forms are 1 3/8" in diameter.

|

|

|

|

|

|

|

|

|

|

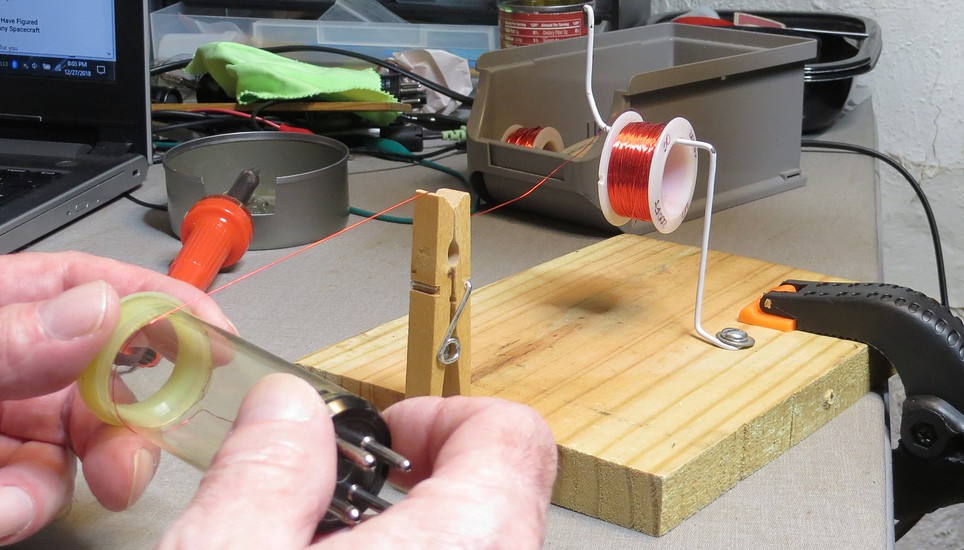

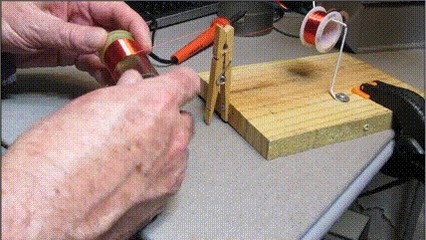

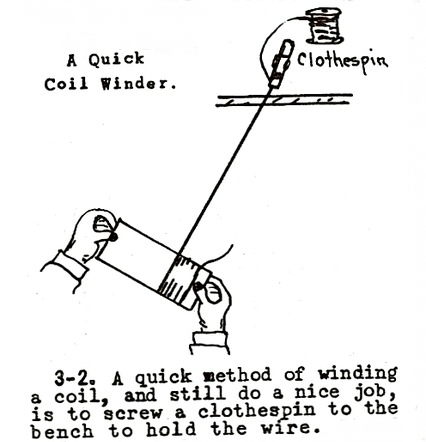

To wind the coil you need tension on

the wire. This can be done by passing the wire through a hole in a

clothespin (an idea from one of Elmer's handbooks).

Scrape the insulation from the end of the wire. Drill or melt (with

a hot pin) a hole

in the top of the coil form, pass the wire through the clothespin,

into the hole, and into pin 1.

Heat the pin with a soldering iron. Solder will wick into the

hole, soldering the wire to the pin.

When the coil is wound, hold it in place with a piece of tape. Drill

or melt a hole in the form, scrape the insulation from the end of the wire, and pass the

wire through the hole and into pin 2. |

|

|

|

|

- Click on image -

MRL coil winder from HB-6 "How To Make Coils."

|

|

After you wind the main coil, wind the tickler coil

in the same manner. I found that trying to get the bottom tickler

winding wire into pin 4 was almost impossible due to how close the

hole in the bottom of the coil form was to the pin. The fix for this

is to hold the winding in place with a piece of tape and leave about

a foot of wire on the end. Scrape off the insulation at the

appropriate place. Push the wire through the hole in the form, bring

it out the top, then loop it around and insert it into the pin. Pull

it tight and solder. |

|

|

|

|

|

|

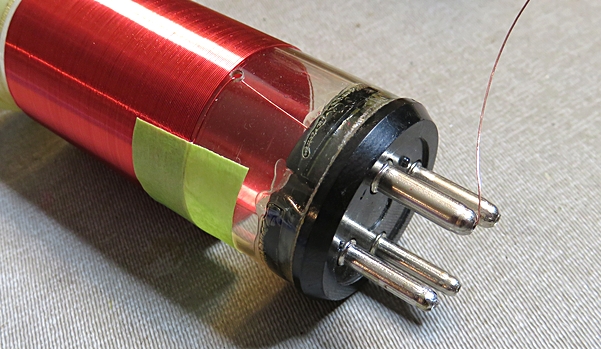

The completed coil. It tunes from below the broadcast band up to about 1100 kHz.

Two coils are needed to cover the entire band. |

|

|

|

| The second coil, on the left. It tunes from

around 900 kHz to 1750 kHz. Next to it is an MRL coil that covers

about the same range. I try not to handle the Elmer Osterhoudt MRL coils too much.

The coil on the left is wound on an MRL form made by Paul Nelson in

2015. |

|

|

|

|