|

|

|

|

|

|

|

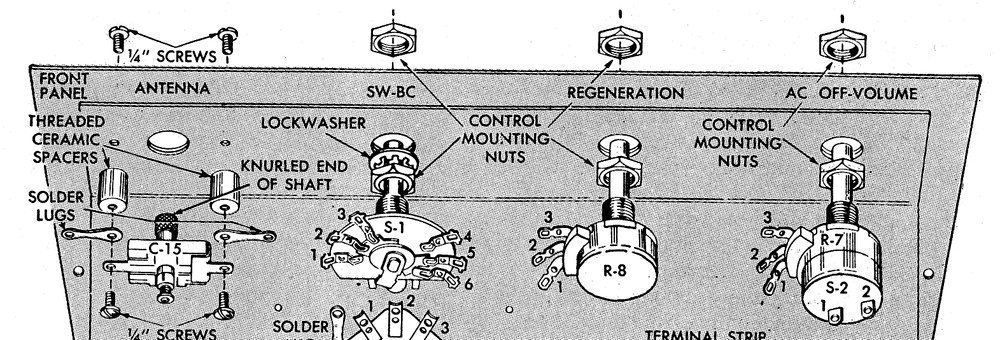

...the answer was,

"I have the radio, and the controls aren't mounted like yours. They are mounted with one hex nut behind

the panel so that only a minimum amount of the threaded

bushing extends through the panel. Your suspicions are

correct.

Vince" |

|

|

|

|

|

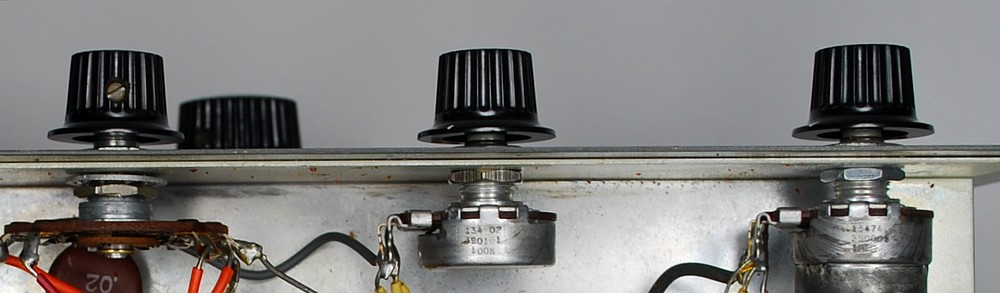

A few minutes later, Vince

sent this picture. Click on it for full size.

OK, let's think

about this. I wanted to keep the radio original. However, if

James had skipped the steps where he was supposed to mount

the hex nuts, the radio isn't going to look right. He used

the lock washer behind the bandswitch control, but didn't

bother with the hex nut. We'll never know why. Perhaps the

neighborhood bully shook him down for hex nuts.

At any rate, the controls were going to get the hex nuts so

the radio looks right. |

|

|

|

PROBLEM! |

|

|

|

|

|

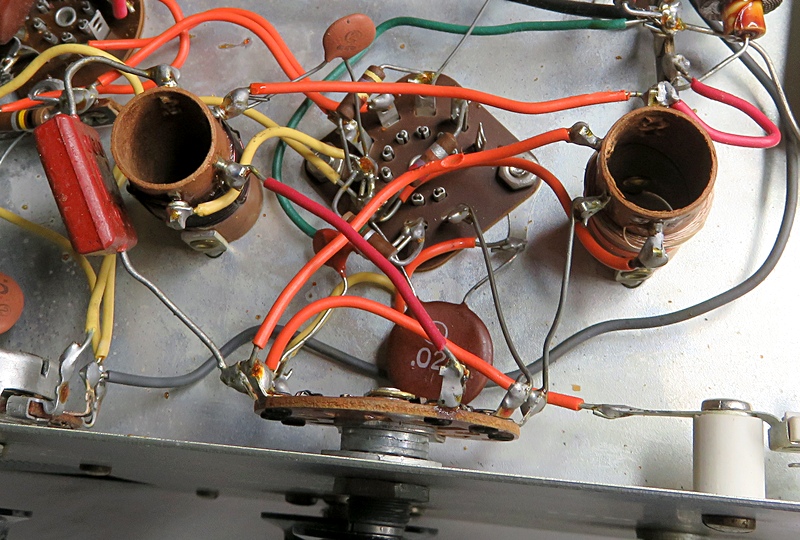

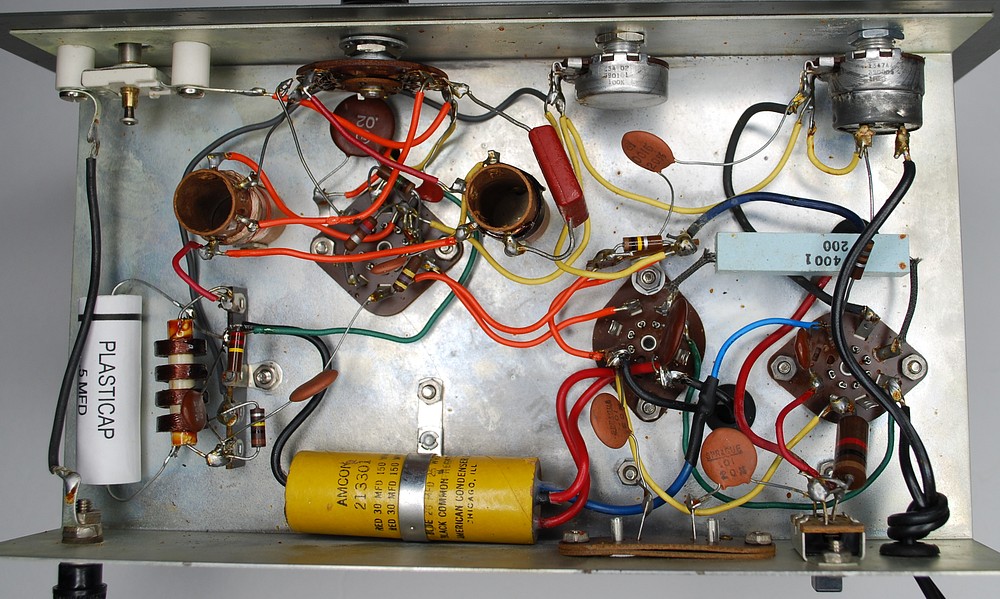

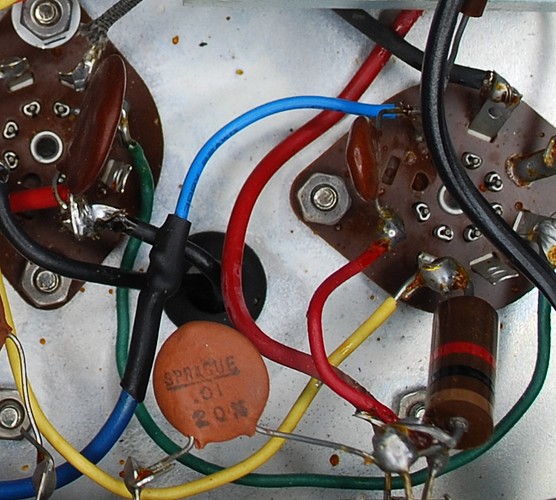

Now there is a

problem. How can you back the bandswitch out with everything

connected to it? You can't, mostly because of the heavy

leads on the big brown capacitor on the left. It goes from

the switch to the coil and the leads might as well be pieces

of coat hanger, they're so stiff. Should I start unsoldering everything? What

if something gets damaged?

Just then, this came in from the radio forum: "Did you

try unbolting the coil to see if you could move it and the

switch enough to put on the nut and washer? You might also

have to unbolt the 12AT7 socket. Be very careful with the

connections on the coils. They were really only intended for

one soldering operation.

Jay" |

|

|

|

|

|

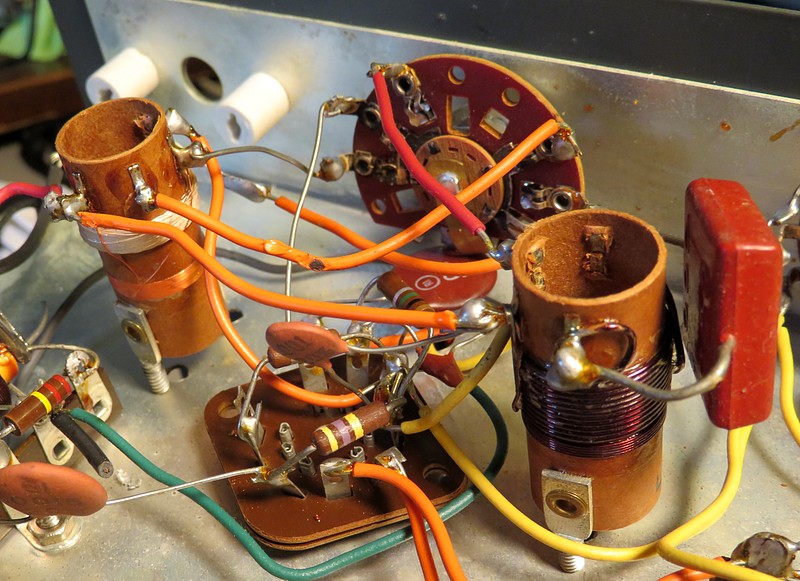

That was the answer! In this photo both coils and the

tube socket have been detached and everything is slowly being backed

out.

|

|

|

|

|

|

Success! |

|

|

|

|

|

The knobs are now in their

proper positions in relation to the front panel. |

|

|

|

|

|

|

RE-STUFFING CAPACITORS |

|

|

|

|

|

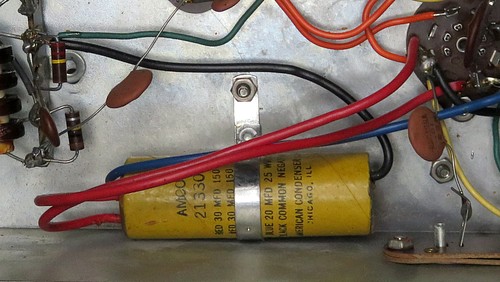

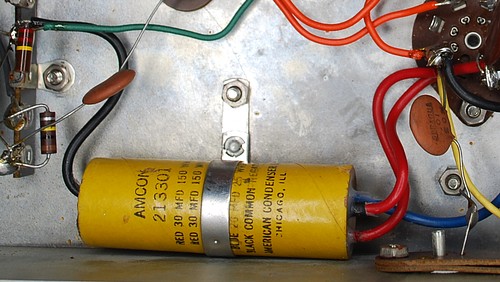

For some reason, James

installed the filter capacitor facing backwards. This means we can

reuse the wire! |

|

|

|

|

|

The new capacitors are rated at 160 volts, 10 volts

higher than the old ones. |

|

|

|

|

|

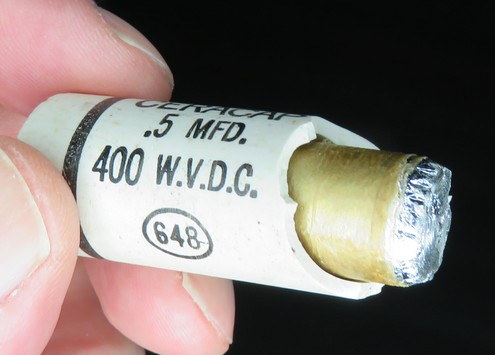

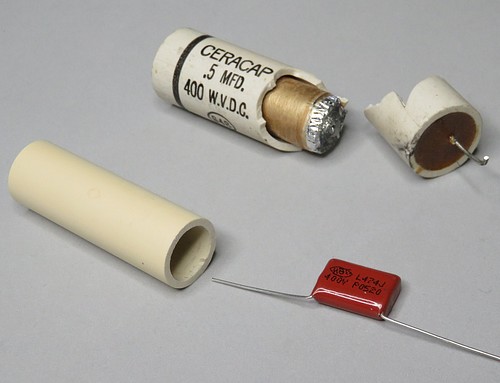

There is a big ceramic covered

capacitor labeled "CERACAP" which I broke while

trying to melt the plastic out of the ends. The wax

inside boiled and the pressure burst the ceramic

apart. Next time, I'll drill a hole in the end

first. Ironically, there was probably nothing wrong

with it.

Interesting that inside is a lit cigar butt. No

wonder these radios smoke. |

|

|

|

|

|

|

The ceramic was replaced with PVC. It's now

called a "PLASTICAP." |

|

|

|

|

|

| |

|

|

All done.

That was fairly easy. A voltage check showed all the voltages to be

higher than predicted in the manual.

That's because the radio is expecting to see 110 volts AC, but our

outlets are testing at 121 volts AC. |

|

| |

|

|

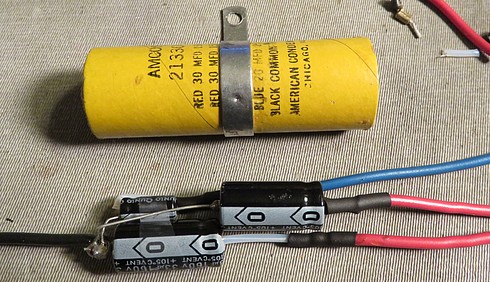

| My only regret. The re-stuffed filter

capacitor had been sitting on the kitchen table for a few

days. I absent mindedly picked it up one night and cut all

the leads to the same length so it would look nice. When I

went to install it, the blue wire was about a millimeter too

short. DOH!! |

|

|

| |

|

|

The knobs were soaked overnight in soapy

water and then polished. Thankfully, nobody called me on the

phone during the polishing operation and asked what I was

doing. (Nudge nudge, wink wink.)

The white pointers are craft paint. Very easy to use, you

carefully fill the indentation, let it dry, and then scrape

the excess off with a thumbnail. The results are excellent.

The knobs are marked "DAKA-WARE CHICAGO" on the back. They

were manufactured by Davies Molding Co. and are made of phenolic plastic |

|

|

| |

|

|

| Refurbished Space Spanner. |

| |

|

|

| Here's a short video showing the

Space Spanner in action. |

| |

| |

|

| |

|

|

| |