|

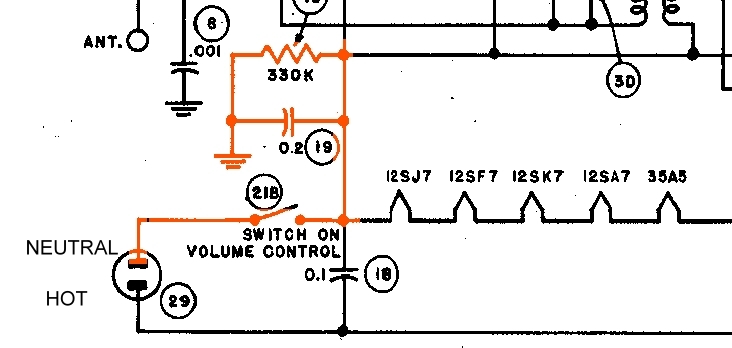

Westinghouse

model H-126

"Little Jewel" |

|

|

|

|

|

|

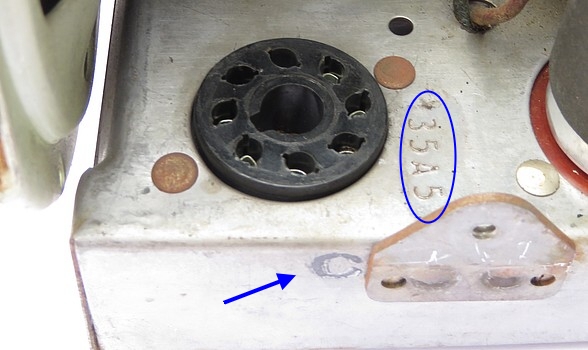

| Dating the radio: These

radios were manufactured between 1945 and 1949. Because of a

scarcity of 35A5 vacuum tubes, the 35A5 tube socket on this

radio has been changed so that it now accepts a 35L6. On the

side of the chassis near the tube socket is the letter "C"

to indicate a change in the design. This change went into

effect either June 20, 1946 or July 11, 1946 (depending on

where you get the information.) Therefore, the radio was made between the

second half of 1946 and 1949. |

|

|

|

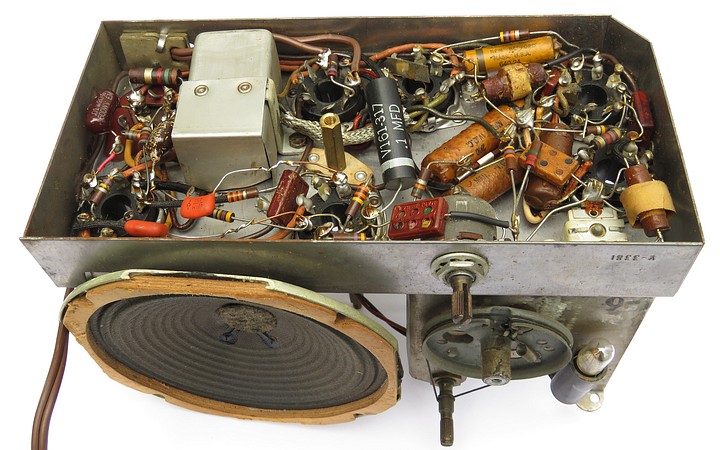

Under the chassis. I "repaired" this in

1987 by replacing capacitors till it started working. |

|

|

|

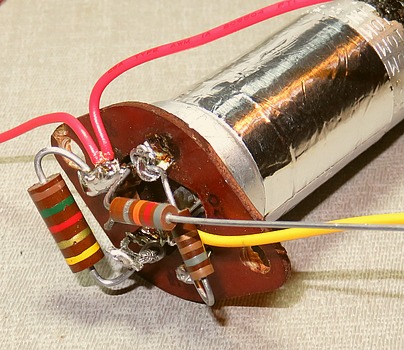

The filter capacitor has a cardboard cover! That

means we can operate on it and then put the cover back on.

There are three capacitors in the metal can. The reason for the

cover is that the can is stamped with the wrong values.

As if there weren't already enough parts in this radio, the

cardboard sleeve had to be added to the metal can to show the

correct values inside.

|

|

|

|

|

| Connected to the three

filter capacitors are four rubber coated wires that need to

be replaced. The rubber

insulation shattered when I cut the wires. |

|

|

|

|

|

|

To re-stuff the can, you

need to cut the wires, drill out the rivets, remove the socket with

the can from the chassis, cut it open and pull out the antique capacitors.

In this case, the paper electrolyte material was still sticky. I didn't know what

the sticky stuff was, so I ate some of it to see if it was

toxic in case I had to wash my hands after touching it.

Actually, the sticky electrolyte material is made of Borax

and Ethylene Glycol (anti-freeze.)

|

|

|

|

|

|

|

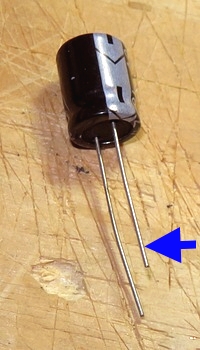

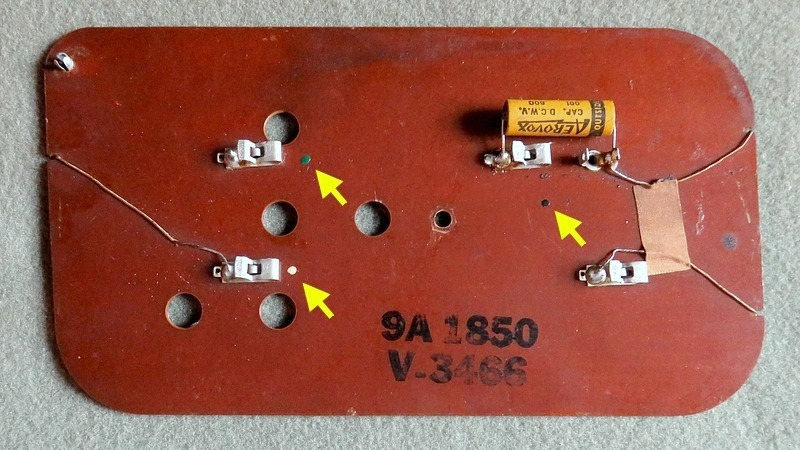

Holes were drilled in

the cleaned-out base for the new caps. It needs two 50uf @

150 volts and one 20uf @ 25 volts. In the left hand

photo I've marked where the positive lead of the 20uf

capacitor goes. If I get this mixed up, 120 volts will go

through the 25 volt cap.

The "clever" plan was to use all 160 volt caps as a

fail-safe. If I got a 50uf cap mixed up with the 20uf cap it

might not make much of a difference as long as they were all

rated at 160 volts. It was a darn good plan if you ask me.

Unfortunately, the negative leads were too short to allow

them to spread out the way I envisioned they would be, so

they are all crammed into one side of the can. I had to use

a smaller 50 volt 20uf cap to get all three of them to fit in there.

So much for my clever plan. Next time I'll find capacitors

with longer leads. *

* A perfect example of a "brain freeze." I

could have soldered wires to the leads to extend them. |

|

|

|

|

|

|

|

Because the area in the chassis is so

tight to work in, I added some of the components before

putting the can back in place. |

|

|

|

|

|

|

|

Before and After. |

|

|

|

|

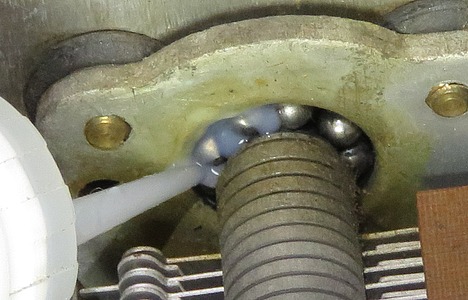

| The bearings in the

tuning capacitor are bone dry, as is to be expected. The

chassis is turned on its side when it's in the case. In this

position, the

12SJ7 vacuum tube is situated directly under the tuning

capacitor and heats it up. The heat from the 35L6 also heats

it up. The grease in these bearings probably melted an hour

after the original owner fired this thing up in the 1940s. |

|

|

| |

|

|

| I used 100% Teflon to

lube the bearings. This dispenser is sold in bicycle shops

to lube bicycle chains. I put some in the toaster oven at

250 ̊ F. It didn't melt. |

|

|

|

|

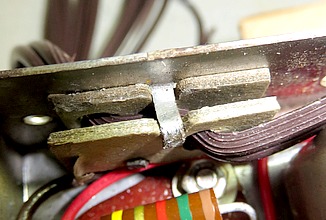

If you are restoring

one of these radios and the strain relief for the AC cord is

missing, this is what it looks like. I believe it was one

piece, with a paper hinge. The fact that it is no longer

hinged makes no difference. You can make these out of poster

board or some other heavy paper material. Notice how they

are keyed and the way the cord is routed.

Mount the cord in the strain relief first, then solder the connections. Or

if you like, you can slide the strain relief parts onto the cord, solder

the cord in place and then attempt to mount the strain

relief. After you realize you gave no thought to the order

the pieces go together, you can cut the cord off and start

over, like I did. |

|

|

| |

| |

|

|

|

| I let the knobs soak

overnight in soapy water and all those flecks of paint came

off. Once they were clean, the scratches in them became very

apparent. Some 1000 grit sandpaper and plastic polish took

care of them. They look new if you don't get too close. |

|

|

|

For the sake of appearance, the old

capacitor on the antenna was stuffed with a new one.

There are colored dots to show you where the wires are

connected when you reattach it to the radio. |

|

|

|

|

Here's the little No. 47 pilot lamp, made by General

Electric. It looked to be as old as the radio, so it

was replaced. General

Electric was formed in 1892 when the Edison General

Electric Company, founded by Thomas Edison, merged

with the Thomson-Houston Company. A week after this

bulb was replaced, November 13, 2017, General

Electric CEO John Flannery announced that the

company is getting out of the lighting business

after 139 years.

Maybe I should put the bulb back in the radio since

there seems to be some cosmic connection with

current events. On the other hand, GE also made

vacuum tubes. I don't think putting a GE vacuum tube

in the radio would start them making vacuum tubes

again.

Ironically, Thomas Edison invented the diode vacuum

tube and never realized it. |

|

|

|

|

|

| There is only one route from

the AC outlet to the chassis. A polarized plug was wired as above. |

|

| After checking the resistors,

it was time to plug the radio in and hear how well it works! |

|

| |

|

|

| |